FIBER OPTIC CABLES

OUTDOOR CABLES

Aerial Figure-8 Cables, Capacity up to 264 fibers

CCSI Standard Aerial Figure-8 Optical Fiber Cables

Technical Specification

GENERAL |

The cable is for outdoor application installed as overhead between city poles up to 100-m span for aerial networks.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.655.C, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Requires no grounding on cable core part

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Supporting Strength Element Figure-8 |

– Galvanized steel messenger wire 7 x Ø1.2 mm

| High Density Polyethylene (HDPE) jacket |

– Black UV resistant High Density Polyethylene (HDPE) jacket as outer protection

– Good abrasion & scratch resistance

– Excellent weathering and UV resistance

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.215 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.210 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.6 ± 0.4 | 9.2 ± 0.4 / 10.4 ± 0.5 |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER :

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

Multimode OM3 and OM4 fibers are available upon request

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |||||||

| Fiber Quantity | 4 – 30 | 12 – 60 | 72 | 84 – 96 | 108 – 144 | 156 – 216 | 228 – 312 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Loose Tube Quantity | 5 | 5 | 6 | 8 | 12 | 18 | 26 | |

| Number of Active Tubes | 1 – 5 | 1 – 5 | 6 | 7 – 8 | 9 – 12 | 13 – 18 | 19 – 26 | |

| Cable Dimension | Cable Diameter (Nominal) | 10.0 mm | 11.0 mm | 11.5 mm | 13.0 mm | 15.5 mm | 16.5 mm | 19.0 mm |

| Cable Height (Nominal) | 19.5 mm | 20.0 mm | 21.0 mm | 22.0 mm | 25.0 mm | 25.5 mm | 28.0 mm | |

| Cable Weight (Nominal) | 175 kg/km | 185 kg/km | 195 kg/km | 225 kg/km | 285 kg/km | 290 kg/km | 375 kg/km | |

MECHANICHAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 2900 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 2500 N/ 100 mm |

| Impact Strength Radius (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength (Refer to IEC 60794-1-2-E10) | 5 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 10 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Telkom Standard Aerial Figure-8 Optical Fiber Cables

Technical Specification

GENERAL |

The cable is for outdoor application installed as overhead between city poles up to 100-m span for aerial networks.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.655.C, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, STEL K-017-2009, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured dual-layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Supporting Strength Element Figure-8 |

– Galvanized steel messenger wire 7 x Ø1.2 mm

| High Density Polyethylene (HDPE) jacket |

– Black UV resistant High Density Polyethylene (HDPE) jacket as outer protection

– Good abrasion & scratch resistance

– Excellent weathering and UV resistance

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C | ITU-T G.655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 / 1625 | 1550 / 1625 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.215 | 0.215 / 0.30 | 0.210 / 0.35 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.215 | 0.215 / 0.30 | 0.210 / 0.35 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 at 1310 nm | 9.6 ± 0.4 at 1550 nm | 9.6 ± 0.4 at 1550 nm | 9.2 ± 0.4 at 1310 nm |

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |||

| Fiber Quantity | 4 – 36 | 24 – 72 | 60 – 96 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | |

| Loose Tube Quantity | 6 | 6 | 8 | |

| Number of Active Tubes | 1 – 6 | 2 – 6 | 5 – 8 | |

| Cable Dimension | Cable Diameter (Nominal) | 12.0 mm | 13.0 mm | 14.5 mm |

| Cable Height (Nominal) | 21.0 mm | 22.0 mm | 23.5 mm | |

| Cable Weight (Nominal) | 200 kg/km | 215 kg/km | 255 kg/km | |

MECHANICHAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 2900 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 2500 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength (Refer to IEC 60794-1-2-E10) | 10 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Direct Buried Cables, Capacity up to 216 fibers

Corrugated Steel Tape Armored Direct Buried Single Jacket Optical Fiber Cables

Technical Specification

GENERAL |

The cable is for outdoor, underground inside HDPE ducts. The installation may use air-assisted (air-blown) method, water pressure-floating or manual pulling.

REFERENCE STANDARDS

The offered fiber optic cable complies to the the ITU-T G.652.D, ITU-T G.654.B, ITU-T G.654.C, ITU-T G.655.C, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, TIA/ EIA standards. Fiber type is optional, following to the customer request.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked |

– Each fibers are inserted into thixotropic gel-filled coloured dual – layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Corrugated Steel Tape Armor |

– Provides rodent bite protection for direct buried applications

| High Density Polyethylene (HDPE) jacket |

– Black UV resistant High Density Polyethylene (HDPE) jacket as outer protection

– Good abrasion & scratch resistance

– Excellent weathering and UV resistance

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.215 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.210 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.60 ± 0.4 | 9.2 ± 0.4 / 10.4 ± 0.5 |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER :

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

Multimode OM3 and OM4 fibers are available upon request.

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |||||||

| Fiber Quantity | 4 – 30 | 12 – 60 | 72 | 84 – 96 | 108 – 144 | 156 – 216 | 228 – 312 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Loose Tube Quantity | 5 | 5 | 6 | 8 | 12 | 18 | 26 | |

| Number of Active Tubes | 1 – 5 | 1 – 5 | 6 | 7 – 8 | 9 – 12 | 13 – 18 | 19 – 26 | |

| Cable Dimension | Cable Diameter (Nominal) | 10.5 mm | 11.0 mm | 12.5 mm | 13.5 mm | 16.0 mm | 16.5 mm | 19.0 mm |

| Cable Weight (Nominal) | 105 kg/km | 115 kg/km | 145 kg/km | 170 kg/km | 235 kg/km | 250 kg/km | 330 kg/km | |

MECHANICAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 2900 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 4500 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength Radius (Refer to IEC 60794-1-2-E10) | 5 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 10 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Telkom Standard Direct Buried Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for outdoor, direct burial, inside HDPE ducts, or on cable trays or on cable ladders.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.655.C, ITU-T G.655.D, IEC 60794-3, STEL K-016-2009 versi 2.1, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked |

– Each fibers are inserted into thixotropic gel-filled coloured dual – layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Double Polymer Coated Aluminium Tape |

– Aluminium tape as a mositure barrier

| Corrugated Steel Tape Armor |

– Provides rodent bite protection for direct buried applications

| High Density Polyethylene (HDPE) jacket |

– Black UV resistant High Density Polyethylene (HDPE) jacket as outer & inner protection

– Good abrasion & scratch resistance

– Excellent weathering and UV resistance

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.215 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.210 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 at 1310 nm 10.4 ± 0.5 at 1550 nm | 9.60 ± 0.4 at 1550 nm | 9.2 ± 0.4 at 1310 nm 10.4 ± 0.5 at 1550 nm |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

Multimode OM3 and OM4 fibers are available upon request.

CABLE PARAMETERS

| ITEM | SPECIFICATION | ||||||

| Fiber Quantity | 4 – 36 | 24 – 72 | 60 – 96 | 120 – 144 | 120 – 216 | 240 – 264 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | 12 | 12 | 12 | |

| Loose Tube Quantity | 6 | 6 | 8 | 12 | 18 | 22 | |

| Number of Active Tubes | 1 – 6 | 2 – 6 | 5 – 8 | 10 – 12 | 10 – 18 | 20 – 22 | |

| Cable Dimension | Diameter (Nominal) | 17.0 mm | 18.0 mm | 20.0 mm | 22.5 mm | 23.5 mm | 25.0 mm |

| Weight (Nominal) | 255 kg/km | 285 kg/km | 320 kg/km | 435 kg/km | 450 kg/km | 520 kg/km | |

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 3000 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 4500 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength Radius (Refer to IEC 60794-1-2-E10) | 5 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 10 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Duct Metallic Cables, Capacity up to 312 fibers

CCSI Standard Duct Metallic Optical Fiber Cables

Technical Specification

GENERAL |

The cable is for outdoor, underground inside HDPE ducts. The installation may use air-assisted (air-blown) method, water pressure-floating or manual pulling.

REFERENCE STANDARDS

The offered fiber optic cable complies to the the ITU-T G.652.D, ITU-T G.654.B, ITU-T G.654.C, ITU-T G.655.C, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, TIA/ EIA standards. Fiber type is optional, following to the customer request.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured dual-layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Requires no grounding

– More flexible

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| High Density Polyethylene (HDPE) jacket |

– Black UV resistant High Density Polyethylene (HDPE) jacket as outer protection

– Good abrasion & scratch resistance

– Excellent weathering and UV resistance

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.654.B | ITU-T G.654.C | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Cut-Off Shifted Single Mode | Cut-Off Shifted Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1550 | 1550 / 1625 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.180 | 0.180 | 0.215 / 0.35 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.175 | 0.175 | 0.210 / 0.35 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4at 1310 nm | 11.9 ± 0.5at 1550 nm | 9.9 ± 0.5at 1550 nm | 9.6 ± 0.4at 1550 nm | 9.2 ± 0.4at 1550 nm |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER :

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

Multimode OM3 and OM4 fibers are available upon request.

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |||||||

| Fiber Quantity | 4 – 30 | 12 – 60 | 72 | 84 – 96 | 108 – 144 | 156 – 216 | 228 – 312 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Loose Tube Quantity | 5 | 5 | 6 | 8 | 12 | 18 | 26 | |

| Number of Active Tubes | 1 – 5 | 1 – 5 | 6 | 7 – 8 | 9 – 12 | 13 – 18 | 19 – 26 | |

| Cable Dimension | Cable Diameter (Nominal) | 9.0 mm | 9.5 mm | 10.0 mm | 11.5 mm | 14.0 mm | 14.5 mm | 17.5 mm |

| Cable Weight (Nominal) | 60 kg/km | 65 kg/km | 80 kg/km | 100 kg/km | 130 kg/km | 160 kg/km | 230 kg/km | |

MECHANICAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 2900 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 2500 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength (Refer to IEC 60794-1-2-E10) | 5 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 10 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Telkom Standard Duct Optical Fiber Cables

Technical Specification

GENERAL |

The cable is for outdoor, underground inside HDPE ducts. The installation may use air-assisted (air-blown) method, water pressure-floating or manual pulling.

REFERENCE STANDARDS

The offered fiber optic cable complies to the the ITU-T G.652.D, ITU-T G.655.C, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, STEL K-015-2013, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured dual-layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Steel wire central strength member |

– Steel wire central strength element as depth tracer

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Double Polymer Coated Aluminium Tape |

– Aluminium tape as a mositure barrier

| High Density Polyethylene (HDPE) jacket |

– Black UV resistant High Density Polyethylene (HDPE) jacket as outer protection

– Good abrasion & scratch resistance

– Excellent weathering and UV resistance

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C | ITU-T G.655.D | ITU-T G.657.A1 | |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending Loss Insensitive Single Mode | |

| Wavelength (nm) | 1310 / 1550 | 1550 / 1625 | 1550 / 1625 | 1310 / 1550 | |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.215 | 0.215 / 0.30 | 0.210 / 0.35 | 0.35 / 0.20 | |

| Typical Attenuation (dB/km) | 0.35 / 0.215 | 0.215 / 0.30 | 0.210 / 0.35 | 0.35 / 0.19 | |

| Mode Field Diameter (µm) | 9.2 ± 0.4 at 1310 nm | 9.6 ± 0.4 at 1550 nm | 9.6 ± 0.4 at 1550 nm | 9.2 ± 0.4 at 1310 nm | |

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |||||||

| Fiber Quantity | 4 – 36 | 24 – 72 | 60 – 96 | 120 – 144 | 120 – 216 | 240 – 264 | 288 – 312 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Loose Tube Quantity | 5 | 6 | 8 | 12 | 18 | 22 | 26 | |

| Number of Active Tubes | 1 – 6 | 2 – 6 | 5 – 8 | 10 – 12 | 10 – 18 | 20 – 22 | 24 – 26 | |

| Cable Dimension | Cable Diameter (Nominal) | 11.5 mm | 12.5 mm | 14.0 mm | 17.5 mm | 18.0 mm | 19.5 mm | 21.0 mm |

| Cable Weight (Nominal) | 110 kg/km | 130 kg/km | 165 kg/km | 245 kg/km | 255 kg/km | 295 kg/km | 335 kg/km | |

MECHANICAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 2900 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 2200 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength (Refer to IEC 60794-1-2-E10) | 10 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 cpm, 10 minutes, 2 direction @ 180˚ |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Aerial ADSS Non Metallic Cables, Capacity up to 312 fibers

Aerial All Dielectric Self Supporting (ADSS) Optical Fiber Cables

Technical Specification

GENERAL |

The cable is for outdoor application installed as aerial cable on up to 100-m pole distance (span) or as duct cable installed inside HDPE sub duct

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.655.C, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured dual – layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| All-dielectric cable construction |

– Requires no grounding

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

– Aramid yarns as a tensile strength element

| High Density Polyethylene (HDPE) jacket |

– Black UV resistant High Density Polyethylene (HDPE) jacket as outer protection

– Good abrasion & scratch resistance

– Excellent weathering and UV resistance

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.215 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.210 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.60 ± 0.4 | 9.2 ± 0.4 / 10.4 ± 0.5 |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER :

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

Multimode OM3 and OM4 fibers are available upon request.

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |||||||

| Fiber Quantity | 4 – 30 | 12 – 60 | 72 | 84 – 96 | 108 – 144 | 156 – 216 | 228 – 312 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Loose Tube Quantity | 5 | 5 | 6 | 8 | 12 | 18 | 26 | |

| Number of Active Tubes | 1 – 5 | 1 – 5 | 6 | 7 – 8 | 9 – 12 | 13 – 18 | 19 – 26 | |

| Cable Dimension | Cable Diameter (Nominal) | 9.0 mm | 9.5 mm | 10.0 mm | 11.5 mm | 14.0 mm | 14.5 mm | 17.5 mm |

| Cable Weight (Nominal) | 60 kg/km | 65 kg/km | 80 kg/km | 100 kg/km | 130 kg/km | 160 kg/km | 230 kg/km | |

MECHANICAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 2900 N |

| Minimum Sagging | 1% of span distance |

| Wind Speed (Maximum) | 100 km/hour |

| Crush Strength (Refer to IEC 60794-1-E3) | 2500 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength Radius (Refer to IEC 60794-1-2-E10) | 5 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 10 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

INDOOR CABLES

FTTH Loose Tube Design (CCSI Standard Design Cables)

CCSI Standard FTTH Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for short span overhead outdoor with span distance up to 60 meters for last mile cable. The cable is also applicable for indoor and outdoor areas.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.657.A1, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Bending Loss Insensitive Fibers |

– 2 Fibers (Blue & Orange) single mode ITU-T Rec. G.657.A1 bending loss insensitive optical fibers

| Non-Metallic anti-buckling strength element |

– GRP/FRP Ø 0.4 mm x 2

– Protect the optical fibers from any excessive elongation and tensile loads that occur during installation and operation

| Anti-Rodent material |

– Provides rodent bite protection

| Supporting Strength Element Figure-8 |

– Galvanized steel messenger wire rod 1 x Ø1.2 mm as aerial cable holder

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath as outer protection

– The thermoplastic sheath does not promote the growth of fungus and be free of pits, splits and blisters

– Reduces the amount of toxic and corrosive fume emission

– Other sheathing are available upon request

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.657.A1 |

| Type | Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.2 ± 0.4 / 10.4 ± 0.5 |

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 2 | |

| Cable Dimension | Height (Nominal) | 5.0 mm |

| Width (Nominal) | 2.0 mm | |

| Weight (Nominal) | 20 kg/km | |

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 130 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 1200 N/ 250 mm |

| Impact Strength Radius (Refer to IEC 60794-1-E4) | 3 Nm |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 1 meter, 30 cpm,10 minutes |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

CCSI Standard FTTH Aerial Figure-8 Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for short span overhead outdoor with span distance up to 60 meters for last mile cable. The cable is also applicable for indoor and outdoor areas.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.657.A1, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Bending Loss Insensitive Fibers |

– 2 Fibers (Blue & Orange) single mode ITU-T Rec. G.657.A1 bending loss insensitive optical fibers

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection

| Central loose tube design |

– Single loose tube

| Anti-Rodent material |

– Provides rodent bite protection

| Supporting Strength Element Figure-8 |

– Galvanized steel messenger wire 7 x Ø0.4 mm as aerial cable holder

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath as outer protection

– Reduces the amount of toxic and corrosive fume emission

– Other sheathing are available upon request

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.657.A1 |

| Type | Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.2 ± 0.4 / 10.4 ± 0.5 |

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 2 | |

| Loose Tube Quantity | 1 | |

| Cable Dimension | Cable Diameter (Nominal) | 3.0 mm |

| Cable Height (Nominal) | 5.7 mm | |

| Cable Weight (Nominal) | 22 kg/km | |

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 160 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 1200 N/ 250 mm |

| Impact Strength Radius (Refer to IEC 60794-1-E4) | 3 Nm |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 1 meter, 300 twists |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

FTTH Loose Tube Design (Telkom Standard Design Cables)

CCSI FTTH Flat Telkom Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for short span overhead outdoor with span distance up to 60 meters for last mile cable. The cable is also applicable for indoor and outdoor areas.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.657.A1, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Bending Loss Insensitive Fibers |

– 2 Fibers (Blue & Orange) single mode ITU-T Rec. G.657.A1 bending loss insensitive optical fibers

| Non-Metallic anti-buckling strength element |

– GRP/FRP Ø 0.4 mm x 2

– Protect the optical fibers from any excessive elongation and tensile loads that occur during installation and operation

| Anti-Rodent material |

– Provides rodent bite protection

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath as outer protection

– The thermoplastic sheath does not promote the growth of fungus and be free of pits, splits and blisters

– Reduces the amount of toxic and corrosive fume emission

– Other sheathing are available upon request

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.657.A1 |

| Type | Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.2 ± 0.4 / 10.4 ± 0.5 |

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 2 | |

| Cable Dimension | Height (Nominal) | 3.0 mm |

| Width (Nominal) | 2.0 mm | |

| Weight (Nominal) | 12 kg/km | |

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 130 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 1200 N/ 250 mm |

| Impact Strength Radius (Refer to IEC 60794-1-E4) | 3 Nm |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 1 meter, 30 cpm,10 minutes |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

CCSI FTTH Telkom Aerial Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for short span overhead outdoor with span distance up to 60 meters for last mile cable. The cable is also applicable for indoor and outdoor areas.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.657.A1, IEC 60794, TIA/ EIA standards

CONSTRUCTIONS |

CABLE STRUCTURE

| Bending Loss Insensitive Fibers |

– 2 Fibers (Blue & Orange) single mode ITU-T Rec. G.657.A1 bending loss insensitive optical fibers

| Non-Metallic anti-buckling strength element |

– GRP/FRP Ø 0.4 mm x 2

– Protect the optical fibers from any excessive elongation and tensile loads that occur during installation and operation

| Anti-Rodent material |

– Provides rodent bite protection

| Supporting Strength Element Figure-8 |

– Galvanized steel messenger wire rod 1 x Ø1.2 mm as aerial cable holder

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath as outer protection

– The thermoplastic sheath does not promote the growth of fungus and be free of pits, splits and blisters

– Reduces the amount of toxic and corrosive fume emission

– Other sheathing are available upon request

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.657.A1 |

| Type | Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.2 ± 0.4 / 10.4 ± 0.5 |

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 2 | |

| Cable Dimension | Height (Nominal) | 5.0 mm |

| Width (Nominal) | 2.0 mm | |

| Weight (Nominal) | 20 kg/km | |

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 130 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 1200 N/ 250 mm |

| Impact Strength Radius (Refer to IEC 60794-1-E4) | 3 Nm |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 1 meter, 30 cpm,10 minutes |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Flare Flex

CCSI Flame Retardant Flare Flex Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for indoor, on cable trays/ ladders including underground installation and inside conduits.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.651, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection using swellable material

| Central loose tube design |

– Single loose tube

| Anti-Rodent material |

– Provides rodent bite protection

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath as outer protection

– Reduces the amount of toxic and corrosive fume emission

– Other sheathing are available upon request

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D |

| Type | Single Mode |

| Wavelength (nm) | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 | |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 | |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 | |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 | |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 | |

Multimode OM3 and OM4 fibers are available upon request.

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 4 – 12 | |

| Loose Tube Quantity | 1 | |

| Cable Dimension | Outer Diameter (Nominal) | 6.0 mm |

| Weight (Nominal) | 45 kg/km | |

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 1000 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 1000 N/ 250 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 5 Nm |

| Kink Strength (Refer to IEC 60794-1-E11) | 5 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 10 x Cable Outside Diameter |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

SPECIAL CABLES

Flame Retardant Corrugated Steel Tape Armored (CSTA)

Flame Retardant Corrugated Steel Tape Armored Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for outdoor, direct burial, inside HDPE ducts, or on cable trays or on cable ladders.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.655.C, ITU-T G.655.D, IEC 60794-3, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked |

– Each fibers are inserted into thixotropic gel-filled coloured dual – layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Corrugated Steel Tape Armor |

– Provides rodent bite protection for direct buried applications

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath as outer protection

– The thermoplastic sheath does not promote the growth of fungus and be free of pits, splits and blisters

– Reduces the amount of toxic and corrosive fume emission

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.215 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.210 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.60 ± 0.4 | 9.2 ± 0.4 / 10.4 ± 0.5 |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

Multimode OM3 and OM4 fibers are available upon request.

CABLE PARAMETERS

| ITEM | SPECIFICATION | |||||||

| Fiber Quantity | 4 – 30 | 12 – 60 | 72 | 84 – 96 | 108 – 144 | 156 – 216 | 228 – 312 | |

| Maximum Fibers per Tube | 6 | 12 | 12 | 12 | 12 | 12 | 12 | |

| Loose Tube Quantity | 5 | 5 | 6 | 8 | 12 | 18 | 26 | |

| Number of Active Tubes | 1 – 5 | 1 – 5 | 6 | 7 – 8 | 9 – 12 | 13 – 18 | 19 – 26 | |

| Cable Dimension | Cable Diameter (Nominal) | 10.5 mm | 11.0 mm | 12.5 mm | 13.5 mm | 16.0 mm | 16.5 mm | 19.0 mm |

| Cable Weight (Nominal) | 105 kg/km | 115 kg/km | 145 kg/km | 170 kg/km | 235 kg/km | 250 kg/km | 330 kg/km | |

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 2900 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 4500 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength Radius (Refer to IEC 60794-1-2-E10) | 5 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 10 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

Fire Resistant Corrugated Steel Tape Armored (CSTA)

Fire Resistant Corrugated Steel Tape Armoured Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for indoor, outdoor, direct burial for underground networks. The cable can also be installed on cable trays and on cable ladders

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, IEC 60332-3A,

TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured dual-layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Corrugated Steel Tape Armor |

– Provides rodent bite protection for direct buried applications

| Fire Resistant |

– Fire resistant tape applied around the middle jacket

– Used in vital communication and emergency systems that remains operated even during a fire

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath

– Reduces the amount of toxic and corrosive fume emission

– Other sheathing are available upon request.

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.215 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.210 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.60 ± 0.4 | 9.2 ± 0.4 / 10.4 ± 0.5 |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 4 – 30 | |

| Maximum Fibers per Tube | 6 | |

| Loose Tube Quantity | 5 | |

| Number of Active Tubes | 1 – 5 | |

| Cable Dimension | Outer Diameter (Nominal) | 15.5 mm |

| Weight (Nominal) | 280 kg/km | |

Other Fiber Type and Fiber Quantity are available upon request.

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 3000 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 4500 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 12 Nm |

| Kink Strength (Refer to IEC 60794-1-2-E10) | 10 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

FIRE RESISTANT GALVANIZED STEEL WIRE ARMORED (GSWA) CABLE

Fire Resistant Galvanized Steel Wire Armoured Optical Fiber Cables

Technical Specification

GENERAL |

The cable is applicable for above ground, on cable tray/ rack, inside building, at swampy area, in the river or underground.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.652.D, ITU-T G.655.D, ITU-T G.657.A1, IEC 60794-3, IEC 60332-3A, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable |

– Each fibers are inserted into thixotropic gel-filled coloured dual-layer thermoplastic (PC-PBT) loose buffer tubes

– Water ingression protection is applied using swellable compound and tape

| Dielectric central strength member |

– Glass reinforced plastic (GRP/FRP) non-metallic, anti buckling central strength element

| SZ-stranded |

– Isolates fibers from installation and environmental rigors

– The loose buffer tube and fillers are SZ-stranded around FRP and bound with polyester yarns

| Double Polymer Coated Aluminium Tape |

– Aluminium tape as a mositure barrier

| Corrugated Steel Tape Armor |

– Provides rodent bite protection for direct buried applications

| Galvanized Steel Wire Armour |

– Provides mechanical protection, the cable can withstand high tensile stress

– Galvanized Steel Wire Armour 2.6 mm diameter X 18 wires

– Other armour size and quantity are available upon on request

| Fire Resistant |

– Fire resistant tape applied around the middle jacket

– Used in vital communication and emergency systems that remains operated even during a fire

| Low Smoke Zero Halogen Flame Retardant (LSZH FR) jacket |

– Black UV resistant Low Smoke Zero Halogen Flame Retardant (LSZH FR) sheath

– Reduces the amount of toxic and corrosive fume emission

– Other sheathing are available upon request.

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.655.C & 655.D | ITU-T G.657.A1 |

| Type | Single Mode | Non-Zero Dispersion Shifted (NZDSF) Single Mode | Bending-Loss Insensitive Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1310 / 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.215 | 0.35 / 0.20 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.210 | 0.35 / 0.19 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 / 10.4 ± 0.5 | 9.60 ± 0.4 | 9.2 ± 0.4 / 10.4 ± 0.5 |

FIBER PARAMETERS OF MULTIMODE OPTICAL FIBER

| Core / Cladding Diameter (µm) | 50/125 | 62.5/125 |

| Reference Standard | ITU-T G.651.1 | TIA – EIA – 568 – B.3 |

| Wavelength (nm) | 850 / 1300 | 850 / 1300 |

| Attenuation on Finished Cables (dB/km) | 3.0 / 0.8 | 3.5 / 1.5 |

| Modal Bandwidth – length product for overfilled launch (MHz.km) | 500 / 500 | 160 / 500 |

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 4 – 30 | |

| Maximum Fibers per Tube | 6 | |

| Loose Tube Quantity | 5 | |

| Number of Active Tubes | 1 – 5 | |

| Cable Dimension | Outer Diameter (Nominal) | 26.5 mm |

| Weight (Nominal) | 1450 kg/km | |

Other Fiber Type and Fiber Quantity are available upon request.

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Operating Tensile Strength (Refer to IEC 60794-1-E1) | 80000 N |

| Crush Strength (Refer to IEC 60794-1-E3) | 6000 N/ 100 mm |

| Impact Strength (Refer to IEC 60794-1-E4) | 15 Nm |

| Kink Strength (Refer to IEC 60794-1-2-E10) | 10 x Cable Outside Diameter |

| Minimum Bending Radius (Refer to IEC 60794-1-E11) | 15 x Cable Outside Diameter |

| Torsion (Refer to IEC 60794-1-E7) | 30 twists, 2 direction @ 180˚, Load 250N |

| Water Ingression Resistance (Refer to IEC 60794-1-F5B) | Passed with 1-m cable sample, 24 hours,1-m water column height pressure |

| Operating & Storage Temperature | Up to 70° C |

SUBMARINE CABLES

Submarine fiber optic cables connect most of the world’s human, businesses and institutions. Lying on ocean floors, these submarine cable systems carry the vast majority of our international communications and data. Together, they form the backbone for the data centers powering the world wide web.

Within continental repeater system submarine cable stretch thousands of kilometer with repeaters span within 70 km to 90 km where 6 pairs fiber are ultimate due to total cost system. Higher pair in system difficult due to numbers of repeaters, size and energy supply system complexity.

In area where coastal contributes the most of connectivity, repeater-less system are cost effective, the span stretch 600 km away has been proven no requirement of any repeater. Thank for the EDFA and RAMAN amplification combination system that no longer any wet plant electrical power component needed. Although 12 pairs can carry large capacity but much higher fiber counts also applicable for shorter span where totaly free from EDFA or RAMAN.

CCSI set in Indonesia, focus on repeater less submarine cable system build to suit to Indonesia archipelagos rich of coastal cities. At the gland of capacity reach to 3000 km a year and comprises of cables family Light Weight, Single Armor, Double Armor and and Rock Armor. CCSI with domestic content reach more then 40%, in house build joint closure, and shore end solution will contribute to submarine cable system integrator to gain benefit in region for both cost and logistic.

CCSI submarine cables has been certified and approved to use UNIVERSAL QUICK JOINT, adding an international quality recognition of it’s products.

Submarine Light Weight (LW) Optical Fiber Cables

Technical Specification

GENERAL |

The offered cable is UQJ qualified for undersea application down to 5000m ocean depth for burial or surface laid.

This Light Weight cable can be spliced using flexible joint closure or Universal Quick Joint (UQJ).

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.976, G.978, ITU-T G.652.D, ITU-T G.654.B, ITU-T G.654.C, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable– All wires interstices are filled with bitumen |

| Stainless Steel Loose Tube |

– Stainless steel central loose tube with thixotropic gel filling as fiber protection

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as inner protection

| Galvanized Steel Wire Armour |

– Provides mechanical protection, the cable can withstand higher stress

– Galvanized steel wire armoured 12 x Ø1.7 mm for inner armouring over the stainless steel central loose tube

– Other armour size and quantity are available upon on request

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as outer protection

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.654.B | ITU-T G.654.C |

| Type | Single Mode | Cut-Off Shifted Single Mode | Cut-Off Shifted Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.180 | 0.180 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.175 | 0.175 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 at 1310 nm | 11.4 – 12.4 at 1550 nm | 9.4 – 10.4 at 1550 nm |

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |

| Fiber Quantity | 24 | |

| Cable Dimension | Cable Diameter (Nominal) | 12.8 mm |

| Cable Weight in the Air (Nominal) | 350 kg/km | |

| Cable Weight in the seawater (Nominal) | 277 kg/km | |

| Specific Gravity | Specific gravity in the air | 2.71 g/cm3 |

| Specific gravity in the sea water | 2.15 g/cm3 | |

Other Fiber Type and Fiber Quantity are available upon request.

MECHANICAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Cable Breaking Load (CBL) | 50 kN (minimum) |

| Nominal Transient Tensile Strength (NTTS) | 30 kN |

| Nominal Operation Tensile Strength (NOTS) | 20 kN |

| Nominal Permanent Tensile Strength (NPTS) | 10 kN |

| Minimum Bending Radius with load (MBR) | 800 mm |

| Minimum Bending Radius without load | 600 mm |

| Operating temperature | -10˚C up to +50˚C |

| Storage temperature | -30˚C up to +70˚C |

| Water depth application | 5000 m (maximum) |

| Hydro dynamic constant | 0.7 m/s |

Submarine Single Armour (SA) Optical Fiber Cables

Technical Specification

GENERAL |

The offered cable is UQJ qualified for undersea application down to 1500m ocean depth for burial or surface laid. This Single Armour cable can be spliced using flexible joint closure or Universal Quick Joint (UQJ).

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.976, G.978, ITU-T G.652.D, ITU-T G.654.B, ITU-T G.654.C, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

| Fully waterblocked cable– All wires interstices are filled with bitumen |

| Stainless Steel Loose Tube |

– Stainless steel central loose tube with thixotropic gel filling as fiber protection

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as inner protection

| Galvanized Steel Wire Armour |

– Provides mechanical protection, the cable can withstand higher stress

– Galvanized steel wire armoured 12 x Ø1.7 mm for inner armouring over the stainless steel central loose tube

– Galvanized steel wire armoured 18 x Ø2.6 mm for outer armouring layers

– Other armour size and quantity are available upon on request

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as inner protection

| PP Yarn Protection |

– Polypropylene (PP) yarns in yellow and black colours as sacrificial protection over the wire armouring.

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.654.B | ITU-T G.654.C |

| Type | Single Mode | Cut-Off Shifted Single Mode | Cut-Off Shifted Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.180 | 0.180 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.175 | 0.175 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 at 1310 nm | 11.4 – 12.4 at 1550 nm | 9.4 – 10.4 at 1550 nm |

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |

| Fiber Quantity | 24 | |

| Cable Dimension | Cable Diameter (Nominal) | 23.0 mm |

| Cable Weight in the Air (Nominal) | 1200 kg/km | |

| Cable Weight in the seawater (Nominal) | 950 kg/km | |

| Specific Gravity | Specific gravity in the air | 2.88 g/cm3 |

| Specific gravity in the sea water | 2.28 g/cm3 | |

Other Fiber Type and Fiber Quantity are available upon request.

MECHANICAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Cable Breaking Load (CBL) | 200 kN (minimum) |

| Nominal Transient Tensile Strength (NTTS) | 175 kN |

| Nominal Operation Tensile Strength (NOTS) | 125 kN |

| Nominal Permanent Tensile Strength (NPTS) | 60 kN |

| Minimum Bending Radius with load (MBR) | 1000 mm |

| Minimum Bending Radius without load | 800 mm |

| Operating temperature | -10˚C up to +50˚C |

| Storage temperature | -30˚C up to +70˚C |

| Water depth application | 1500 m (maximum) |

| Hydro dynamic constant | 0.9 m/s |

Submarine Double Armour (DA) Optical Fiber Cables

Technical Specification

GENERAL |

The offered cable is UQJ qualified for undersea application down to 600m ocean depth for burial or surface laid. This Double Armour cable can be spliced using flexible joint closure or Universal Quick Joint (UQJ).

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.976, G.978, ITU-T G.652.D, ITU-T G.654.B, ITU-T G.654.C, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

Fully waterblocked cable

– All wires interstices are filled with bitumen

| Stainless Steel Loose Tube |

– Stainless steel central loose tube with thixotropic gel filling as fiber protection

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as inner protection

| Galvanized Steel Wire Armour |

– Provides mechanical protection, the cable can withstand higher stress

– Galvanized steel wire armoured 12 x Ø1.7 mm for inner armouring over the stainless steel central loose tube

– Galvanized steel wire armoured 18 x Ø2.6 mm and 24 x Ø2.6 mm for outer armouring layers

– Other armour size and quantity are available upon on request

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as inner protection

| PP Yarn Protection |

– Polypropylene (PP) yarns in yellow and black colours as sacrificial protection over the wire armouring.

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER :

| Reference Standard | ITU-T G.652.D | ITU-T G.654.B | ITU-T G.654.C |

| Type | Single Mode | Cut-Off Shifted Single Mode | Cut-Off Shifted Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.180 | 0.180 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.175 | 0.175 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 at 1310 nm | 11.4 – 12.4 at 1550 nm | 9.4 – 10.4 at 1550 nm |

CABLE PARAMETERS :

| ITEM | SPECIFICATION | |

| Fiber Quantity | 24 | |

| Cable Dimension | Cable Diameter (Nominal) | 28.0 mm |

| Cable Weight in the Air (Nominal) | 2200 kg/km | |

| Cable Weight in the seawater (Nominal) | 1740 kg/km | |

| Specific Gravity | Specific gravity in the air | 3.57 g/cm3 |

| Specific gravity in the sea water | 2.82 g/cm3 | |

Other Fiber Type and Fiber Quantity are available upon request.

MECHANICAL CHARACTERISTICS :

| ITEM | SPECIFICATION |

| Cable Breaking Load (CBL) | 400 kN (minimum) |

| Nominal Transient Tensile Strength (NTTS) | 300 kN |

| Nominal Operation Tensile Strength (NOTS) | 250 kN |

| Nominal Permanent Tensile Strength (NPTS) | 100 kN |

| Minimum Bending Radius with load (MBR) | 1200 mm |

| Minimum Bending Radius without load | 900 mm |

| Operating temperature | -10˚C up to +50˚C |

| Storage temperature | -30˚C up to +70˚C |

| Water depth application | 600 m (maximum) |

| Hydro dynamic constant | 1.2 m/s |

Submarine Rock Armour (RA) Optical Fiber Cables

Technical Specification

GENERAL |

The offered cable for undersea application down to 600m ocean depth for burial or surface laid.

REFERENCE STANDARDS

The offered fiber optic cable complies to the ITU-T G.976, G.978, ITU-T G.652.D, ITU-T G.654.B, ITU-T G.654.C, IEC 60794, TIA/ EIA standards.

CONSTRUCTIONS |

CABLE STRUCTURE

Fiber Identification

– Each fiber is coloured with durable bright transparent colour

– Every twelve coloured fibers is bundled with coloured polyester yarn or ink-jet dotted to distinguish with other twelve fibers

| Fully waterblocked cable |

– All wires interstices are filled with bitumen

| Stainless Steel Loose Tube |

– Stainless steel central loose tube with thixotropic gel filling as fiber protection

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as inner protection

| Galvanized Steel Wire Armour |

– Provides optimal mechanical protection, the cable can withstand higher stress

– Galvanized steel wire armoured 12 x Ø1.7 mm for inner armouring over the stainless steel central loose tube

– Galvanized steel wire armoured 15 x Ø4.0 mm and 21 x Ø4.0 mm for outer armouring layers

– Other armour size and quantity are available upon on request

| High Density Polyethylene (HDPE) |

– Black UV resistant High Density Polyethylene (HDPE) as inner protection

| Polypropylene Yarn Protection |

– Polypropylene (PP) yarn roving in yellow and black colours as sacrificial protection over the wire

PARAMETERS |

FIBER PARAMETERS OF SINGLE MODE OPTICAL FIBER

| Reference Standard | ITU-T G.652.D | ITU-T G.654.B | ITU-T G.654.C |

| Type | Single Mode | Cut-Off Shifted Single Mode | Cut-Off Shifted Single Mode |

| Wavelength (nm) | 1310 / 1550 | 1550 | 1550 |

| Attenuation on Finished Cables (dB/km) | 0.35 / 0.20 | 0.180 | 0.180 |

| Typical Attenuation (dB/km) | 0.35 / 0.19 | 0.175 | 0.175 |

| Mode Field Diameter (µm) | 9.2 ± 0.4 at 1310 nm | 11.4 – 12.4 at 1550 nm | 9.4 – 10.4 at 1550 nm |

CABLE PARAMETERS

| ITEM | SPECIFICATION | |

| Fiber Quantity | 24 | |

| Cable Dimension | Outer Diameter (Nominal) | 37.5 mm |

| Weight in the Air (Nominal) | 4235 kg/km | |

| Weight in the seawater (Nominal) | 3365 kg/km | |

| Specific Gravity | Specific gravity in the air | 3.84 g/cm3 |

| Specific gravity in the sea water | 3.05 g/cm3 | |

Other Fiber Type and Fiber Quantity are available upon request.

MECHANICAL CHARACTERISTICS

| ITEM | SPECIFICATION |

| Cable Breaking Load (CBL) | 350 kN (minimum) |

| Nominal Transient Tensile Strength (NTTS) | 240 kN |

| Nominal Operation Tensile Strength (NOTS) | 170 kN |

| Nominal Permanent Tensile Strength (NPTS) | 140 kN |

| Minimum Bending Radius with load (MBR) | 1500 mm |

| Minimum Bending Radius without load | 1000 mm |

| Operating temperature | -10˚C up to +50˚C |

| Storage temperature | -30˚C up to +70˚C |

| Water depth application | 600 m (maximum) |

| Hydro dynamic constant | 1.2 m/s |

HDPE PIPES

Subduct

Technical Specification

GENERAL |

The raw material of Polyethylene (PE) pipes is classified as High Density Polyethylene (HDPE) PE-100 compound with ultra violet (UV) resistant, corrosion resistant and nonconductive. PE-100 material is an excellence balance between 3 (three) main properties: Stress Cracking, Pressure and Impact Resistances, make it safe to install the pipes at severe conditions such as no dig technique or sandless trench installation. CCSI HDPE pipes are designed to be flexible, lightweight, durable, non-toxic, easy to install and smooth in inner and outer layer with uniform thickness, strong and safe joining systems. These product application is for direct underground buried installation by open continuous trenching, plowing, directional boring, pulled into existing duct or conduit and also ideal for cable jetting installation methods.

REFERENCE STANDARDS

The offered HDPE subduct pipes complies to the STEL L-039-2008 version 2.2 Spesifikasi Telekomunikasi Pipa HDPE Untuk Kabel Serat Optik

CONSTRUCTIONS |

PIPE MATERIAL

| High Density Polyethylene (HDPE) PE-100 class |

– Natural and black color with excellent weathering and ultra violet resistance

– Excellent mechanical properties

– The third generation of pipes grade material designation which have long term hydrostatic strength in 50 years service lifetime

– Resistance to Slow Crack Growth and Rapid Crack Propagation (RCP)

– Compliance with FDA regulation 21 CFR177.152

| Additive and Colorant Masterbatch |

– The resin carrier and additive is the same grade of HDPE material

– The additive and colorant imparting other properties into pipes and resulting more advantage

– Designed for outdoor application with highly resistance environmental effected by weather and ultraviolet sunlight

CROSS-SECTIONAL DRAWING HDPE SUBDUCT

PARAMETERS |

High Density Polyethylene PE-100

| Material Designation | PE-100 Natural |

| Density (gram/cm³) | 0.949 |

| Melt index (190°C/5.0 kg) | 0.25 |

| Carbon black content (%) | > 2.0 |

| Carbon black dispersion | < 3 |

| ESCR { 10% Igepal, F50 } (hours) | > 1000 |

| Tensile strength @yield (Mpa) | 23 |

| Tensile strength @break (Mpa) | 30 |

| Elongation @break (%) | >550 |

| Tensile impact strength (kJ/m²) | 500 |

| Flexural modulus (Mpa) | 1000 |

| Rapid crack propagation {S4 test@ 0°C} (bar) | >10 |

| Slow crack growth {notch test@80°C, 9.2bar} (hours) | >500 |

Additive and Colorant Masterbatch

| Specific gravity range (gram/cm³) | 0.950 – 1.00 |

| Melt index range (190°C/5.0 kg) | 0.18 – 0.30 |

| Light fastness ISO grey scale / Blue wool scale (1-8) | ≥7 |

| Weather / migration fastness (1-5) | 5 |

| Heat stability (°C) | 280 |

| Moisture content (%) | >0.1 |

PIPE PARAMETERS AND MECHANICAL PROPERTIES

| ITEM | SPECIFICATION | ||||||

| Size (mm) | 32/26 | 32/27 | 32/28 | 40/33 | 40/34 | 50/42 | 50/44 |

| Inner diameter nominal (mm) | 26.0 | 27.0 | 28.0 | 33.0 | 34.0 | 42.0 | 44.0 |

| Wall thickness (mm) | 3.0 ± 0.25 | 2.5 ± 0.25 | 2.0 ± 0.25 | 3.5 ± 0.25 | 3.0 ± 0.25 | 4.0 ± 0.25 | 3.0 ± 0.25 |

| Outside diameter (mm) | 32.0± 0.30 | 32.0± 0.30 | 32.0± 0.30 | 40.0± 0.30 | 40.0± 0.30 | 50.0± 0.30 | 50.0± 0.30 |

| Weight nominal (kg/km) | 259 | 219 | 178 | 381 | 331 | 548 | 421 |

| Ovality before coiling (%) | 3.0 | ||||||

| Ovality after coiling (%) | 7.0 | ||||||

| Pressure test (Psi) bar | 217.5 (15) | ||||||

| Minimum bending radius (mm) | 355 | 355 | 355 | 440 | 440 | 550 | 550 |

| Tensile strength (N) | ≥3400 | ≥3200 | ≥3000 | ≥5500 | ≥5500 | ≥8000 | ≥8000 |

| Impact Strength (Nm) | 30 | 30 | 30 | 30 | 30 | 40 | 30 |

| Crush (N) | 400 | 400 | 400 | 550 | 550 | 700 | 700 |

| Delivery length (meter) | 400 | 400 | 400 | 200 | 200 | 100 | 100 |

| Operating and storage temperature | Up to 60°C | ||||||

*Available in wide size range upon request

*The type test of mechanical properties refer to IEC 60794, ASTM D2122, ASTM D2444, ASTM D1598, and ASTM D1599.

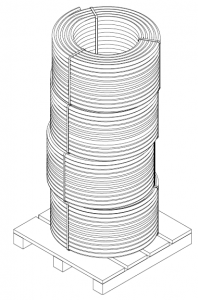

MICRODUCT

Technical Specification

GENERAL |

Microduct is small High Density Polyethylene (HDPE) pipe, which may be in the form of individual pipe or as bundled pipes, and functions as optical fiber micro cable protection in underground application.

HDPE Microduct has the ultra violet (UV) resistant property, non-corrosive and non-conductive with smooth wall to easy micro cable installation. The bundled microducts such as 2-way, 3-way, 4-way, 7-way or other configurations can be deployed at severe conditions such as manual digging, manual boring & pulling techniques or sand-less trench installation.

CCSI microduct is designed to be strong, flexible, lightweight, durable, non-toxic, easy to install and smooth at the inner and outer layers with uniform thickness and easy of jointing. CCSI microduct is for direct underground buried installation or to be pulled into existing duct or conduit, for aerial installation between poles using lashing method and ideal for cable jetting, air blown and even with manual pulling installation.

CCSI microduct typically has small diameter of up to 16.0mm outside diameter, bundled of 2 or more inner-duct with extrusion process. The term of bundled micro-duct described as 2-way, 3 –way, 4-way, 7-way or other configurations according to the client requirements. The advantage of microduct bundled over conventional HDPE subduct are:

- Low initial installation cost, for example 7-way Microduct can be inserted with one micro cable first and then additional cables can be pulled without the need to do digging and install other HDPE ducts for the future expansion.

- Easy to install by inserting to existing duct or occupied duct.

- Ease of branching and jointing

- Micro-ducts and micro cables provide smaller enclosures, enabling operators to place them in most existing vaults and pedestals, saving restoration service time and money. Micro-ducts and micro cables combination affords the compromise of today’s cost versus need in the future

REFERENCE STANDARDS

The offered CCSI HDPE microduct pipes complies to ITU-T-REC-L.79 recommendation and annexes also compliant to IEC 60794-5

CONSTRUCTIONS |

PIPE MATERIAL

| High Density Polyethylene (HDPE) class PE-100 |

– Natural and black color with excellent weathering and ultra violet resistance

– Excellent mechanical properties

– The third generation of pipes grade material designation which have long term hydrostatic strength in 50 years service lifetime

– Resistance to Slow Crack Grow and Rapid Crack Propagation (RCP)

– Compliance with FDA regulation 21 CFR177.152

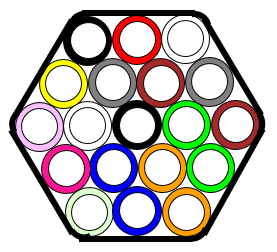

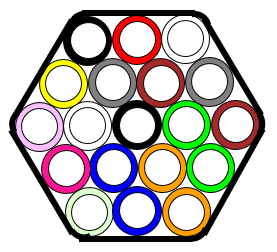

CROSS-SECTIONAL DRAWING HDPE MICRODUCT

PARAMETERS |

High Density Polyethylene PE-100

| Material Designation | PE-100 Natural | HDPE Black |

| Density (gram/cm³) | 0.950 | 0.959 |

| Melt index (190°C/5.0 kg) | 0.25 | 0.25 |

| Carbon black content (%) | – | 2.3 |

| Carbon black dispersion | – | <3 |

| ESCR { 10% Igepal, F50 } (hours) | > 1000 | >100000 |

| Tensile strength @yield (Mpa) | 30 | 26 |

| Tensile strength @break (Mpa) | 50 | 30 |

| Elongation @break (%) | >700 | >600 |

| Tensile impact strength (kJ/m²) | 550 | 500 |

| Flexural modulus (Mpa) | 1300 | 1000 |

| Rapid crack propagation {S4 test@ 0°C} (bar) | >12 | ≥10 |

| Slow crack growth {notch test@80°C, 9.2bar} (hours) | >1058 | >500 |

PIPE PARAMETERS

| ITEM | SPECIFICATION | |||||

| Size (OD x ID) 12/10mm | 2-Way | 3-Way | 4-Way | 7-way | 12-Way | 19-Way |

| Microduct bundling design black PE 1.5mmm outer sheath |  |

|

|

|

|

|

| Colors sequence | Blue, Orange | Blue, Orange, Green | Blue, Orange, Green, Brown | Blue, Orange, Green, Brown, Grey, White, Black | Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Violet, Pink, Turquoise | Blue, Orange, Green, Brown, Grey, White, Black (First layer). Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Violet, Pink, Turquoise |

| Nominal outside diameterwidth x height (mm) | 27.0

x 15.0 |

27.0x

25.0 |

27.0x

27.0 |

36.5x

39.0 |

51.0x

39.0 |

75.0

x 65.0 |

| Nominal Weight (kg/meter) | 0.107 | 0.201 | 0.268 | 0.435 | 0.593 | 0.932 |

| Ovality before coiling (%), refer toASTM D2122-98 | 3.0 | |||||

| Ovality after coiling (%), refer toASTM D2122-98 | 7.0 | |||||

| Pressure test (Psi) bar, refer toASTM D1598-02 | 217.5 (15) | |||||

| Minimum bending radius (mm), refer to IEC 60794-1-2 E11 | 165 | 275 | 300 | 415 | 500 | 670 |

| Tensile strength (N), refer toASTM D638 | 1300 | 2000 | 2700 | 4500 | 7000 | 10000 |

| Impact Strength (Nm), refer toASTM D2444 | 10 | 10 | 10 | 30 | 30 | 30 |

| Crush performance (N,) refer toIEC 60794-1-2 E3 | 750 | 1400 | 1750 | 2000 | 2500 | 3000 |

| Delivery length (meter) | 400 | 400 | 400 | 200 | 100 | 100 |

MECHANICAL PROPERTIES

| ITEM | SPECIFICATION | |||||

| Size (OD x ID) 14/10mm | 2-Way | 3-Way | 4-Way | 7-way | 12-Way | 19-Way |

| Microduct bundling design black PE 1.5mmm outer sheath |  |

|

|

|

|

|

| Colors sequence | Blue, Orange | Blue, Orange, Green | Blue, Orange, Green, Brown | Blue, Orange, Green, Brown, Grey, White, Black | Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Violet, Pink, Turquoise | Blue, Orange, Green, Brown, Grey, White, Black (First layer). Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Violet, Pink, Turquoise |

| Nominal outside diameterwidth x height (mm) | 31.0

x 17.0 |

31.0x

29.0 |

31.0x

31.0 |

41.5x

45.0 |

59.0x

45.0 |

73.0

x 69.5 |

| Nominal Weight (kg/meter) | 0.191 | 0.335 | 0.446 | 0.741 | 0.882 | 1.720 |

| Ovality before coiling (%), refer toASTM D2122-98 | 3.0 | |||||

| Ovality after coiling (%), refer toASTM D2122-98 | 7.0 | |||||

| Pressure test (Psi) bar, refer toASTM D1598-02 | 217.5 (15) | |||||

| Minimum bending radius (mm), refer to IEC 60794-1-2 E11 | 190 | 320 | 345 | 460 | 885 | 785 |

| Tensile strength (N), refer toASTM D638 | 2000 | 2500 | 3200 | 6000 | 8000 | 12000 |

| Impact Strength (Nm), refer toASTM D2444 | 10 | 10 | 10 | 30 | 30 | 30 |

| Crush performance (N,) refer toIEC 60794-1-2 E3 | 1400 | 1600 | 1800 | 2200 | 3000 | 4000 |

| Delivery length (meter) | 400 | 400 | 400 | 200 | 100 | 100 |

*Available in wide size configuration bundled range 8.0 up to 18.0mm outside diameter, microduct accessories and special delivery length upon request. Please contact our marketing for further information.

HIGH DENSITY POLYETHYLENE (HDPE) MICRODUCT WITH 1.2MM OUTER SHEATH FOR FIBER OPTIC CABLE APPLICATION

Technical Specification

GENERAL

All components of this microduct are made based on High Density Polyethylene with UV (Ultra Violet) resistant extrusion material, corrosion free and non-conductive. HDPE microduct has low coefficient friction which will provide an effective fiber optic cable installation time and cost.

- This HDPE microduct is recommended for direct burial underground deployment

- Aerial installation between poles and can be implemented using lashing method

- The cable installation may use cable manufacturer recommendation

This microduct bundle concept is an advance step towards better and more reliable cable network, economical and provides several cable ducts for multi telecom operator usage with only one time installation.

REFERENCE STANDARDS

The CCSI microducts complies to ITU-T-REC-L.79 recommendation and annexes also compliant to IEC 60794-5

PRODUCT CONSTRUCTION

CCSI microduct 3-way 14/10mm is bundled to obtain flexibility, lightweight, durable, easy to install and smooth in inner and outer layer with uniform thickness and color distinguishable UV resistant HDPE material.

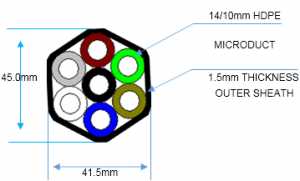

Cross-sectional drawing (Not to scale) figure 1.

| Inner Microduct | Material | High Density Polyethylene (HDPE) |

| Diameter (OD/ID) | 14.0 / 10.0 ± 0.1mm | |

| Thickness | 2.0 ±0.1mm | |

| Color Sequence | Blue, Orange, Green | |

| Number of Element | 3 | |

| Outer Sheathing Microduct | Material | High Density Polyethylene (HDPE) |

| Thickness | 1.2mm (Nominal) | |

| Diameter (WxH) | 30.4 x 28.4 ± 0.2mm | |

| Color | Black |

MECHANICAL PROPERTIES

Inner / Individual Microduct 14/10mm, table 1

| Attributes | Unit | Properties | Standard |

| Ovality Before Coiling | % | ≤ 3 | ASTM D2122-98 |

| Pressure Test | Psi (bar) | 145(10) | ASTM D1598-02 |

| Max Pulling Force | N | 1000 | IEC 60794-1-2 E1 |

Outer Microduct 3 Way 14/10mm, table 2

| Attributes | Unit | Properties | Test Method |

| Weight | Kg/Km | 320 | – |

| Minimum Bending Radius | mm | 350 | IEC 60794-1-2 E11 |

| Tensile Strength | N | 2500 | IEC 60794-1-2 E1 |

| Crush Performance | N | 1600 | IEC 60794-1-2 E3 |

| Ovality After Coiling | % | ≤ 7 | ASTM D2122-98 |

| Impact Load Strength | Nm | 10 | IEC 60794-1-2 E4 |